|

Through our Transfer-in program we have expanded the quantity and range of bullion types we get to inspect. We have not yet come across any suspicious bars but we learned much from a few interesting cases as listed below:

#1 - High Porosity Gold Kilobar

Cross-section of the dissected bar exposes the porosity inside that caused signals to be scattered

We had a case whereby nine serial numbered gold kilobars arrived directly from the mint. Eight of these tested fine, but one bar returned only noise when we ran the ultrasound probe across the length of it. Ultrasound is the most important of DUX tests as it will detect inserts, hollow areas or impurities inside the tested object. As per our company policy, we did not qualify the bar for storage without DUX providing us a satisfactory result.

After trying out different ultrasound detectors and using probes of varying sizes there was still no meaningful signal. Eventually, with permission from the customer / owner of the bar (he shipped his bullion to us through our transfer in program), we sent the bar back to the mint after they agreed to conduct further analysis. The mint eventually reported that - although the bar's surface, purity and mass were as specified - tiny air bubbles/ pores had formed during the manufacturing process. These pores caused ultrasound waves to be scattered and prevented receipt of ultrasound back echoes resulting in the signal noise and thereby masking the bar’s content.

It is important to note that these internal pores did not reduce the bar's mass or purity but rather caused the bar's volume to be slightly larger than usual so the bar was still within specifications. The mint agreed to substitute the bar nonetheless free of charge and sent back a replacement bar for the customer which ‘DUXed’ fine.

#2 - ~1,000 oz Good Delivery Silver Bars, Rough to the Core

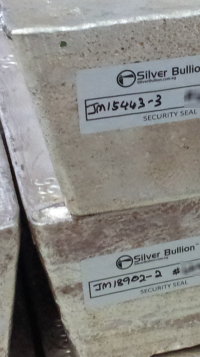

Close-up picture of 1000 oz bars show their porous surface. The suspected large grain further attenuate signals

Good Delivery Silver Bars are produced as cheaply as possible, resulting in large mass variations (see June Newsletter), porous surfaces and large metal grain structures.

When we received our first batch of 22 bars (cast by a major LBMA member) from a transfer-in customer, the tests resulted in unreadable ultrasound returns, making DUX verification impossible. It was only through the dedication of our materials engineer, who physically carried sample bars, to a number of testing labs and ultrasound equipment manufacturers that eventually allowed us to solve the problem.

The primary challenge is that these bars tend to have large grain structures which are likely caused by the slow cooling process during manufacturing. These grain structures make traditional frequency ultrasound probes impractical to use as the soundwaves are greatly attenuated by the large grain. This results in extremely weak back-echoes. A second challenge is the porous surface which requires a different testing setup to ensure all pores are filled with a coupling agent before meaningful ultrasound readings can be done.

Ultimately we had to order an entire new set of dedicated ultrasound detectors, probes and couplants to overcome this grain size problem. Thus, Good Delivery Bars might be the cheapest silver around... but when it comes to authenticating them their roughness (in weight and grainy structures) can be quite costly to compensate for, compared to the more standardized and better finished 100 oz bars.

#3 - Gold Coins and X-Ray Spectrometry, 99.99% vs. 99.87%

One of the DUX tests consists of a surface sample analysis using an X-Ray Spectrometer. These machines give the user a detailed surface composition of the first 20 microns (1/50th of a millimeter) of the metal.

Invasive fire assay on gold coin

We first eliminated the possibility of measurement errors by ensuring the coin is clear of fingerprints or chemicals and repeated the reading with another spectrometer to make sure that a faulty measurement device was not the issue. We then tried a much more expensive spectrometer from the same manufacturer and finally tried a spectrometer from another manufacturer altogether. The results were still around 99.87% (even when allowing for the estimated margin of error) while density and ultrasound readings were fine.

Unwilling to keep the stone unturned, we sent the coin (our own) to undergo destructive fire assay at a local assay laboratory. The laboratory drilled on five spots into the coin, taking five samples of a few grams each and all samples were certified to be 99.99% genuine gold. The coin was thus ruined as a sellable item but we had verified that the coin was indeed 99.99% pure as per specifications regardless of the 99.87% spectrometer surface reading.

The lesson reinforced the understanding that spectrometers measure only a tiny surface cross-section (1/160th of the coin height) and give no indication of what is inside a coin. A tiny scratch on the metal or fingerprint can cause measurements to be off and even if the coin is pristine or in ‘mint’ condition, the manufacturing process involved (i.e. stamping) can embed tiny extraneous substances onto the coin’s surface. Such minuscule impurities can cause a surface reading to register at less than 99.99% even though the coin itself is indeed 99.99% or more in purity.

On a related note, should you ever notice a few tiny red spots on a gold coin these are most likely caused by tiny amounts of silver on the coin's surface that reacted with sulfur in the air, so there is nothing to worry. |